HYDRAULIC CIRCUIT DESIGN

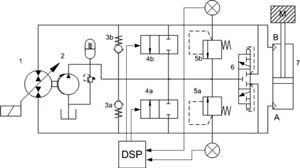

Simple hydraulic circuit; Includes an actuator (jack-cylinder); a steering valve and a simple power pack that includes: a pump, an electro-motor, a pressure switch, and so on.

To design this circuit, we will cover the following steps

First, we must estimate or calculate the required force that is supposed to be produced by the jack (according to the use of the jack)

Hydraulic system pressure selection; according to the standard pressure plate in the hydraulic circuits as well as the pressure of the hydraulic pumps in the market and finally the cost of the parts, the working pressure is selected.

The choice of the pressure that leads to the selection of the pump, the electro-motor and the valves, etc., must be done in such a way that the system will eventually be cost-effective and economical.

It is generally recommended that the pressure should be less than 200 bar. Although hydraulic systems have a pressure of 700 bar and even more, the cost of parts is rising exponentially from 200 to higher, and only when you have to use higher pressures.

By measuring the force and the working pressure of the system, the diameter of the cylinder (jack) can be calculated. The calculated diameter should be taken into account for the diameter numbers of seamless and stamped pipes available on the market, especially for the construction of the jack. The design of the cylinder has not yet been completed and the rod diameter must be calculated based on the cylinder force applied by the rod. The rod's diameter must be calculated so as to prevent the rod from bumping when the maximum force is applied.

Pump Selection and Calculation: Three types of pumps are used in the design of industrial hydraulic circuits: a) Piston pumps: they are generally used for high pressures and thus are expensive. B) gear pumps c) blower pumps.

These last two types are used for low and medium pressure and are available in different types and different flows with reasonable prices in the markets.

In order to select the pump, in addition to the required pressure, the pump flow should be estimated. The system flow will depend on the circuit operator (here the hydraulic jack). To stimate the oil consumption of the jack, we calculate the size of the front and back of the jack. We multiply the sum of these two numbers in the number of performance of the jack per minute (this number is determined by the use of the jack). The result is a liter per minute and or flow of a pump. Now it's just needed to make it clear that the pressure and flow have chosen the most suitable pump from the three types mentioned above. It is important to note that it is usually necessary to overlap the specifications of different types of pumps in a wide range of fields and after technical specifications, finally this is the price which leads a pump selection.

It should be noted that the calculation of flow is so important because if the flow rate is low, the circuit does not have the required speed and if the flow rate is too high, it causes the oil to heat, which causes a lot of problems.

Calculation of electro-motor: according to the specifications obtained for the pump, ie, flow and pressure, the pump power can be calculated. The power of the electro-motor is theoretically the same as the pump power, but in practice a little more (10% to 20%) is considered.

Calculating the size of the pipe and the hoses (internal diameter): It is generally seen that less attention is paid to this sector, while it is of great importance.

If the pipe diameter is less than the required measure, the pipe acts as a neck and the pressure raises the flow and as a result, the system speed is reduced; additional pressure is applied to the pump and the electro-motor that increases the deprecation and the energy consumption also increases.

In hydraulic guides and literature; oil speed recommendations for various oil transfer lines such as pressure lines; return lines and drain lines; (according to the system pressure).

Using these speed recommendations as well as the accuracy of the flow, and a simple calculation, the internal diameter of the pipe (or hose) is calculated.

Seamless hydraulic pipes in the market have standard diameters that we should match their calculated diameters with the size of these pipes; it is recommended that if the size of the calculation is obtained between two pipe sizes, a larger sized tube.

Power Pack Size: Power Pack Oil Volume is considered to be 2 to 3 times the pump flow rate in Lit / Min, and the total volume of the Power Pack is 1 to 15-1.3 times the volume of the oil.

Steering, pressure control and control flow valves: These valves are selected according to the system pressure and flow. They come in many different brands from different countries, and they have a wide range of prices which should be selected and purchased according to the design of the brand and price.

Another important thing to consider when choosing a valve is how to install the valve, which must be determined before the purchase. The possible installation methods are: the block; in the middle of the path; the cartridge; and also the control of the power valve, manual or pneumatic or ...

Consider all these calculations, the specifications of the parts are determined and then it is possible to purchase and close the hydraulic circuit. Although those mention points are related to a simple hydraulic circuit, its possible to generalize to general principles or even complex circuits.

Saman Sanat Pouya Company due to nearly two decades of hydraulic activities and experienced specialists has been able to design and execute all required hydraulic system and circuits. Our consultants are always ready to meet your technical requirements you can contact our experts for more information.

Keywords: Design of hydraulic circuits - Hydraulic system - Hydraulic circuit - From A to Z of hydraulic circuit - From A to Z of circuit design - Implementation of hydraulic map